Coffee packaging is crucial for introducing and selling the product to customers as well as safeguarding the beans during transit.

Coffee packaging, whether it's displayed on a shelf or online, offers information that may influence a customer to choose it over other brands. This covers cost, origins, and any eco-credentials a roaster might have.

According to research, a significant deciding element is the print quality of the product package. Notably, a survey from 2022 discovered that a sizeable portion of consumers are prepared to pay more for goods sold with high-quality photos. Stronger brand trust may result from this in turn.

For coffee roasters, the print quality of the packaging depends depend on the printing method they choose. Printing methods will change as a result of the speciality coffee industry's widespread transition to eco-friendly packaging materials.

How is the quality of package print determined?

Printing for packaging accounts for at least half of all printing today.

Because labels are often printed on adhesive paper that sticks to most surfaces, the packaging material a roaster chooses usually has no impact on the quality of the labels.

Aluminium and petroleum-based plastics have been substituted in coffee packaging with paper and bioplastics, two environmentally beneficial substitutes. These typically take the form of flexible packaging that safeguards the coffee within while not taking up an excessive amount of room during transit or on the store.

Printing is typically outsourced to companies who can handle the necessary volumes. However, this may result in delays and have a negative impact on quality control and personalization.

It's vital to remember that there aren't any standards used to assess print quality. This is due to the fact that it may hinge on a number of objective factors, including contrast, graininess, and the perception of a particular audience.

Additionally, it depends on how intricate the image or print is. This means that roasters will need to think about the packaging material they choose and the printing that will be done on it. They will then need to compare this to the other printing processes, including rotogravure, flexography, UV printing, and digital printing.

How typical packaging materials affect the quality of the print

The print quality of roasters' packaging will be impacted by their decision to prioritize eco-friendly packaging, like coffee kraft or rice paper.

The print quality of some common coffee packaging materials can be impacted in the following ways.

Paper

Kraft paper and rice paper are two common types of paper packaging used in the speciality coffee sector.

Rice paper often comes in a white color and can be printed on in both monochrome and duo-chrome, including on images. Complex patterns and gradient colors, however, could be difficult for it to duplicate.

Additionally, because rice paper is a porous, fibrous texture, ink may not adhere to its surface uniformly. Print variations could result from this in turn.

You can buy bleached or unbleached Kraft paper. Typically white with few limitations, bleached Kraft paper can take a variety of colors.

However, because natural unbleached Kraft paper is brown in color, it looks best when combined with muted, dark colors that complement one another. For instance, white and light colors may not contrast well with the Kraft paper's texture.

Additionally, anything printed on this material will have lower ink strength than on other fabrics due to its high ink absorbency. It is encouraged that roasters refrain from using photographic images in this content because of this.

For a clean design, Kraft paper packaging should ideally have straight lines and few colors. As they are less prone to lose their definition due to the roughness of the paper, heavy fonts are also appropriate.

Plastics and bio plastics

Roasters can select simple-to-recycle plastics like low-density polyethylene (LDPE) or prophylactic acid (PLA), which are bio plastics that are recyclable and biodegradable, depending on the recycling facilities available to their audience.

Plastics with a lot of versatility, like LDPE, are ideal for flexible packaging. It avoids several problems with printing on paper because it is an inert substance.

The material can bend and distort at high temperatures, hence LDPE is not recommended for heat-curing printing.

However, because roasters can opt to print on clear plastic windows and utilize lighter colors, it allows more color diversity for the foreground and background.

PLA functions in printing similarly to LDPE as a bio plastic. It can produce packaging with exceptional clarity and works well with the majority of printing processes and inks.

Choosing a course of action

It is obvious that the packing material a roaster chooses will impact the print quality, but perhaps not to the level initially believed.

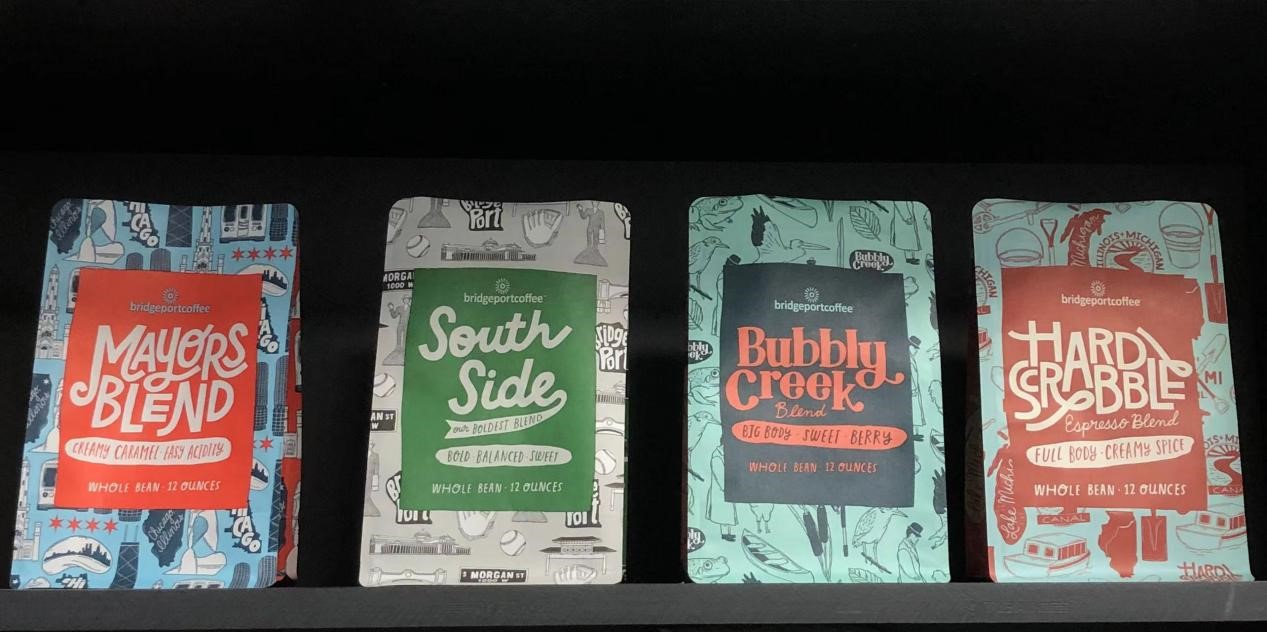

The majority of roasters will want something more complex to set themselves apart from the dozens of other coffees on the market, even though simple, unambiguous designs are generally possible on most materials.

It is suggested that roasters give digital printing priority for this reason. It supports immediate printing with no setup required because it is a dynamic printing form.

Additionally, digital printing enables greater personalization, cooperation, and online and remote design revisions. Additionally, it provides less waste and can reasonably accommodate runs of the minimum order quantity (MOQs) for micro-roasters.

Digital printing delivers better color calibration, characterization, conversion, and feedback in terms of print quality. This implies that the roaster's intended high quality end product is virtually assured.

Built-in sensors guarantee that there are no hue shifts and that high-resolution images with crisp edges, gentle gradients, and solid colors are reliably produced.

Printing for packaging and print quality can be a challenging procedure. However, hiring a professional who can assist with coffee design, printing, and packaging can cut costs for a roaster and expedite delivery of coffee to clients' homes.

Post time: Dec-01-2022