The success of a coffee company’s marketing strategy now heavily depends on its packaging.

Customers are initially drawn in by the packaging even though the coffee’s quality is what keeps them coming back. According to studies, 81% of buyers tried a new product just for the packaging. Furthermore, due to redesigned packaging, more than half of consumers have changed brands.

Consumers are also becoming more and more concerned about how packing materials affect the environment. Roasters must therefore make sure that coffee bags live up to consumer expectations while accurately expressing their brand identity.

Therefore, whether doing a small print run or a large one, roasters will want to ensure that the colors, graphics, and typography used on their coffee packaging are replicated precisely.

There are a number of printing processes to select from, with digital printing being the most recent development, to make appealing and presentable coffee packaging. By printing on recyclable materials, eco-friendly and effective digital printing techniques can help reduce a roaster’s carbon footprint.

Why is printing of the highest caliber so crucial?

Customers today are frequently given a dizzying number of product alternatives, including selections for ground and whole beans of coffee.

When clients have a split second to pick which option to select, packaging is a crucial technique to set a service apart from rivals.

Nevertheless, a recent study found that Gen Z customers prioritize looks while choosing beverage items. Particularly, they are more likely to buy a product with appealing packaging.

The conventional store shelf has also undergone a transformation, moving beyond brick and mortar to become increasingly digital. This implies more brands are vying for the same market share when combined with social media and online sales.

A roaster’s choice of printing method can have a variety of effects on packaging. Quality printing guarantees that, regardless of the type of packaging material used, the design components will be clearly visible and that packaging will appropriately reflect a brand’s identity.

The correct printing method choice will aid in conveying a coffee’s history, tasting comments, and brewing instructions. This can support its pricing and promote brand confidence and loyalty.

What printing methods are available for coffee package printing?

For coffee packaging, rotogravure, flexographic, UV, and digital printing are the most popular printing methods.

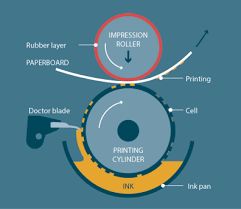

Rotogravure printing uses a printing press to apply ink directly to a cylinder or sleeve that has been laser etched. Before releasing the ink onto a surface, the press has cells that store it in the shapes and patterns necessary to form an image. The ink is then scraped off of areas that do not need color with a blade.

This method is quite affordable because it is exact and the cylinders can be reused. It often only prints one color at a time, though. Because distinct cylinders are needed for each color, it is an expensive investment for short print runs.

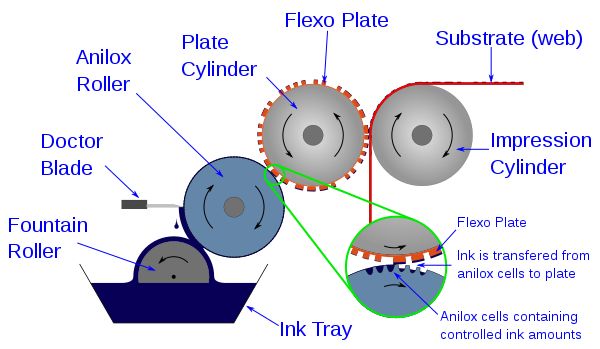

Since the 1960s, flexible printing plates have been used for flexographic printing, which includes transferring ink to the raised surface of the plate before pressing it against the packaging material.

Flexographic printing is extremely accurate and scalable since many plates can be used to add different colors.

Nevertheless, setting up a flaxographic printer might take some time, making it unsuitable for shorter print runs or those that must be completed quickly. It works well for straightforward packaging with little lettering and only two or three colors needed.

As an alternative, UV printing involves adding quickly drying ink to surfaces using LED printers. After that, photo-mechanically evaporated the ink solvents using UV light.It can also print in full color, use eco-friendly inks, and print on a variety of surfaces. It’s crucial to remember that UV inks have greater initial start-up expenses.

Digital printing is the most recent advancement in packaging printing methods. This entails printing text and graphics directly onto surfaces using digital printing presses. Since digital files like PDFs are utilized instead of plates, this is accomplished.

Digital printing is affordable, available on demand, and simple to customize. In addition, the technology could reduce the environmental impact compared to Flexographic and rotogravure printing methods by as much as 80%.

Is digital printing the best and most precise method?

The advantages of digital printing over other types of printing have led to a significant rise in its popularity.

As funds for research and development have been invested over time, it has become available and inexpensive. Additionally, because of its reliance on technology, it is now simpler for businesses to estimate the upfront costs of a print run in terms of capital expenditures, setup, energy use, and labor.

The demand for digital printing surged as a result of the Covid-19 epidemic. Chains of distribution and logistics were stopped during the several global lockdowns.

This inexorably resulted in product shortages, price rises, and delivery delays, which made way for digital printing and its quick turnaround times.

The popularity of flexible packaging that can withstand transport and storage has grown along with e-commerce sales. Additionally, this has boosted the acceptance of digital printing.

While the aforementioned elements are significant, roasters may decide to invest based on the quality of digital printing.

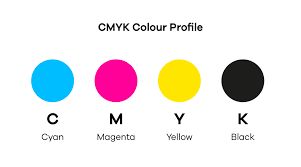

Any color that is needed can be matched by digital printing because it combines the four primary colors of cyan, magenta, yellow, and black. Additionally, it has a maximum toner capacity of seven for improved color coverage.

Through the use of an inline spectrophotometer, color automation is also a common feature of digital printers. For instance, inks are applied using liquid electrophotographic technology using devices like the HP Indigo 25K Digital Press.

Roasters searching for the highest-quality printing method might want to think about investing in digital printing. They might collaborate with specialists in speciality coffee packaging printing for the best outcomes.

CYANPAK is able to satisfy the fast changing roaster needs for a variety of sustainable coffee packaging types, such as compostable and recyclable bags, thanks to our investment in the HP Indigo 25K Digital Press.

This means that we can accommodate low minimum orders (MOQs) with a turnaround time of 40 hours and a shipment time of a day.

Additionally, we may incorporate QR codes, text, or imagery on labels while custom printing coffee bags, which lowers the amount of materials required for printing and lowers the price of packaging. We can support roasters so they may keep offering ecologically friendly products to clients without sacrificing quality of components or aesthetics.

Post time: Dec-02-2022