People frequently can be seen roasting the results of their labor in a sizable pan over an open fire in Ethiopia, which is also referred to be the birthplace of coffee.

Having stated that, coffee roasters are crucial devices that aid in converting green coffee into aromatic, roast beans that support an entire industry.

The market for coffee roasters, for example, was estimated to be worth $337.82 million in 2021 and is projected to grow to $521.5 million by 2028.

The coffee industry has evolved over time, much like any other industry. For instance, the drum roasters that predominate the current business were influenced by the old wood-burning techniques employed in Ethiopia.

Although air-roasting or fluid-bed coffee roasters were first developed in the 1970s, drum roasting is still the older, more conventional process.

Although air-roasting has been used for fifty years, many roasters are only now experimenting with the technique because it is still considered to be novel.

How is coffee air-roasted?

Mike Sivets, a chemical engineer by training, is credited with creating the idea of air-roasting coffee more than 50 years ago.

Mike started his career in the industry by working for General Foods’ instant coffee division, but he didn’t design the fluid bed roaster until after he had left the coffee business.

It is said that when he was given the duty of designing instant coffee factories, he developed an interest in coffee roasters.

At the time, only drum roasters were used to roast coffee, and Mike’s investigation revealed numerous design defects that significantly reduced productivity.

Mike eventually moved on to work in polyurethane production facilities, where he created a fluid bed technique to remove water molecules from magnesium pellets.

German engineers became interested in his work as a result, and soon there were conversations of using the same process for coffee roasting.

This rekindled Mike’s passion in coffee, and he spent time and energy building the first air-roasting machine, a fluid-bed coffee roaster.

Although it took Mike many years to develop a working model that could scale production, his patented design was the industry’s first significant advancement in nearly a century.

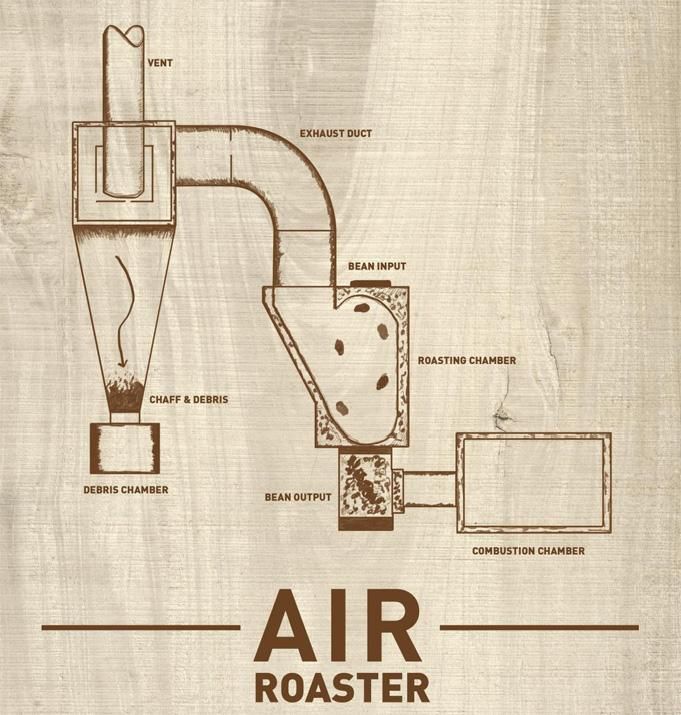

Fluid bed roasters, also known as air roasters, heat the coffee beans by passing a stream of air past them. The name “fluid bed roasting” was created because the beans are raised by this “bed” of air.

Numerous sensors found in a conventional air roaster let you to monitor and regulate the beans’ current temperature. Additionally, air roasters enable you to control elements like temperature and airflow to get the roast you want.

In what ways is air roasting superior to drum roasting?

The way the beans are heated is the key distinction between air roasting and drum roasting.

In the more well-known drum roaster, green coffee is thrown into a rotating drum that has been heated. To guarantee that the roast is even, the drum consistently spins.

Heat is transmitted into the beans in a drum roaster through a combination of around 25% conduction and 75% convection.

As an alternative, air-roasting roasts the beans solely through convection. The air column, or “bed,” maintains the beans’ elevation and guarantees that the heat is dispersed equally.

In essence, the beans are encased in a tightly regulated heated air cushion.

The difference in flavor may be one of the factors driving air roasters’ growth in the speciality coffee sector.

It is significant to remember that who roasts the coffee has a significant impact on the flavor.

But because the machine eliminates the chaff as it roasts, there is less chance of it burning, air roasting won’t likely result in a smokey flavor.

In addition, compared to drum roasters, air roasters tend to produce coffee that is more acidic in flavor.

Compared to drum roasters, air roasters frequently create a consistent roast that tends to deliver a homogenous flavor profile.

What air-roasting coffee does for you

Beyond taste and flavor profiles, standard drum roasters and air roasters differ from one another.

Significant operational variances might also have a big influence on your firm.

One is roast time, for example. Coffee can be roasted in a fluid bed roaster in approximately half the time it takes in a conventional drum roaster.

Particularly for speciality coffee roasters, a shorter roast is less likely to develop undesired chemicals, which frequently give the coffee disagreeable aromas.

A fluid-bed roaster may be the best choice for roasters looking to provide a more accurate picture of the bean attributes.

The second is chaff, an unavoidable byproduct of roasting that poses some risks to your company.

First of all, it is highly combustible and could catch fire if it is not handled cautiously, stopping the entire activity. Smoke production by burning chaff is another factor to take into account.

Fluid bed roasters continuously remove the chaff, removing the potential for chaff combustion to result in a smokey-tasting coffee.

Third, using a thermocouple, air roasters provide a precise reading of the bean temperature.

This provides you with transparent and accurate information about the bean, enabling you to precisely recreate the same roast profile.

Customers will continue to buy from you as a company if your product is consistent.

While drum roasters can accomplish the same thing, doing so frequently calls for the roaster to have more knowledge and expertise.

Compared to conventional drum roasters, air roasters are less likely to require significant adjustments to your current facility in terms of maintenance and infrastructure.

Air roasters may be cleaned more quickly than drum roasters, despite the fact that both kinds of roasting equipment need to be maintained and cleaned.

One of the more environmentally friendly roasting techniques is air-roasting, which cleverly pre-heats the coffee beans using the heat generated during the roasting process.

By minimizing the need to reheat the drum between batches, it is possible to save and recycle energy while lowering carbon dioxide emissions by an average of 25%.

As opposed to conventional drum roasters, air roasters do not require an afterburner, which can help you save energy.

Purchasing recyclable, compostable, or biodegradable coffee packaging and takeaway cups is another option to improve your roasting company’s ecological credentials.

At CYANPAK, we provide a variety of coffee packaging solutions that are 100% recyclable and made from renewable resources like kraft paper, rice paper, or multilayer LDPE packaging with an eco-friendly PLA inner.

Furthermore, we provide our roasters total creative freedom by letting them create their own coffee bags.

You can get assistance from our design staff in coming up with the appropriate coffee packaging. Additionally, we provide custom-printed coffee bags with a short turnaround time of 40 hours and 24-hour shipping time using cutting-edge digital printing technology.

Micro-roasters wishing to maintain agility while showing brand identification and an environmental commitment can also take advantage of CYANPAK’s low minimum order quantities (MOQs).

Post time: Dec-24-2022